| [E-mail] | |||

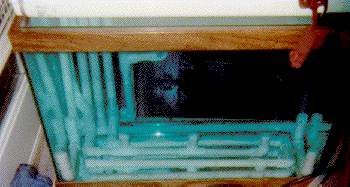

This is front-view picture of the tank in operation prior to adding any

substrate. The water is blue from a dye I added to check water flow patterns.

Vertical tubing in the tank consists of (from left to right):

The horizontal tubing that borders the outside walls of the tank (has towers sticking up at the corners is the diffusion system. The towers are the diffusers and direct water in a clockwise direction in this tank. If you look at the diffuser in the right back corner of the tank, you can just make out the two 1/4" holes drilled in it to direct water. The identical diffuser beside it is a reflection in the glass.

The tubing that lays across the bottom and has three small towers sticking up is the substrate skimmer tubing. The towers are the drains and each has four holes drilled in the cap on top.

The other horizontal tubing in the tank is the nutrient injection system.

This is a picture of the test setup from behind. The tank closest to the

camera is the settling tank. Vertical tubing from right to left in the picture

consists of:

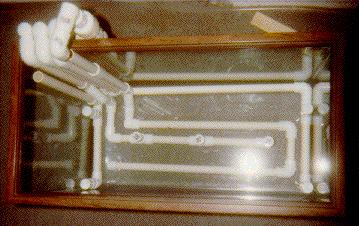

This is a picture of the tank from above. Note the holes drilled in the

substrate skimmer tubing caps to serve as drain grates.

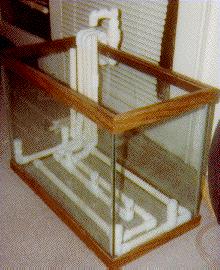

This is a picture of the tank prior to assembly. The tubing may be easier to

see than in the first picture.

This is a picture from above the tank prior to assembly. The camera flash

interfered with this picture some.

This is a picture of the tank, viewed at a diagonal angle prior to assembly.

The hook-shaped tubing above the tank is to prevent water from spilling onto

the carpet if the check valve leaks.

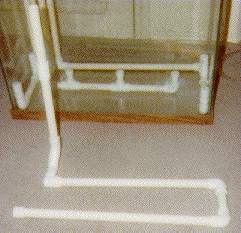

This is a picture of the diffuser system component outside the tank.

This is a picture of the surface skimmer outside the tank.

This is a picture of the substrate flow system (nutrient injection) outside the

tank.

This is a picture of the underside of the substrate flow system. The tube

across the top of the picture has visible perforations along the centerline of

the tube. Perforations in the other tubes are too small for the scanner to

pick out.

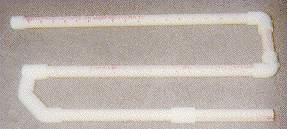

This is a picture of the subsrate skimmer outside the tank.

![[Tank]](tank2t-small.jpg)

This is a photo of my 55g tank right after trimming, a few months prior to

teardown. The PVC tubing inside the tank was used for prototype implementations

of my surface skimmer and substrate skimmer designs. The two anubias nana in

the picture had been moved to the tank's location at the time of the picture

in-tank and had been in-place for over 3 years. The large dark object on the

left wall of the tank is an apple snail.

David W. Webb

Enterprise Computing Provisioning

Texas Instruments Inc. Dallas, TX USA

(214) 575-3443 (voice) MSGID: DAWB (214) 575-4853 (fax) Internet: dwebb-at-ti.com (214) 581-2380 (pager) Text Pager: pgr-at-ti.com Subj:PAGE:David Webb

From dwebb-at-ti.com Sat May 11 23:10:26 1996

Date: Tue, 19 Mar 1996 14:16:22 -0800

From: "David W. Webb" <dwebb-at-ti.com>

To: Erik Olson (e-mail)

Subject: Re: System design photos

[The following text is in the "ISO-8859-1" character set]

[Your display is set for the "US-ASCII" character set]

[Some characters may be displayed incorrectly]

> From: Erik Olson <(e-mail)>, on 3/19/96 11:04 AM:

> Question: did you post an article explaining all this stuff? I do have a

> short description of your overflow skimmer part in the Tech section of

the Krib, but I wonder if your overall article on the fertilization

> system got lost somewhere. If you can point me to a general date you

> posted it, I have all my APDs archived & can pull it from there.

I posted a few articles about these designs over the last 10 months or so. I

found as many of them as I could and included the references below. I also

included the text from two other designs. Note that I modified my

nutrient-injection system (substrate flow system) designs due to space

limitations in the 20g (and my 55g).

As far as I can tell, my first mention on the APD of the substrate flow system

is

here.

The explanation of my substrate flow design is

here.

Further discussion of my tank plans is at:

here.

(I wound up throwing the 50g away.)

I made another mention of my plans

here.

The 40g actually wound up being a 29g and a 20h. I did a vermiculite-sand

substrate on the 20 with a 10g sump and used the 29 for a sump for my 55g. The

laterite experiment will also have to wait until I get another 20g tank.

I talked briefly about my 20h implementation (the one pictured)

here.

I mention an advantage of settling tanks

here.

Charley Bay and I pretty much talked each other into switching to settling

tanks instead of trickle filters.

I talked about my 55g setup, pre-planting

here.

David Whittaker, the first person I know of who implemented my designs, wrote

an article on his "Webb-Kelley tank"

here

and

here.

Here are other articles that I have written for emailing to people:

------------------------------------------------

When I tear my tank down, I'm planning on a sub-gravel plumbing system

with diffusers that stick up a few inches above the gravel and create

a definite lower-level flow pattern.

I'm hoping that this flow will help my plants metabolize nutrients more

effectively by constantly delivering fresh nutrients. I'm also hoping

that this flow pattern will keep the detrius off of the gravel and

plant leaves and help flush it down the trickle filter.

I have a 55 gallon. I am planning to put one diffuser in each corner

and one in the back. I will either attempt to create a counter-

clockwise flow pattern or a half and half flow pattern. I think the

counter-clockwise pattern will take less pump, so that's what I'm

looking at right now.

I am also planning two or three center-drains at the gravel level.

Maybe I'll cover the drains with some coarse gravel so they aren't

visible. I plan to cover the openings for these drains with coarse

mesh to keep from sucking down a fish. These will be plumbed with a

straight siphon for periodic usage and with a loopback (smart) siphon

for continuous usage. Hopefully, opening the ball valve on one of

these will suck down any debris that refuses to follow the current up

to the tank drain.

Under the gravel will also be a substrate aeration system. It will

consist of 1/2" PVC tubing with 2 rows of holes, angled at 90 degrees

from one another. The holes will be positioned at the bottom of

the tube.

I've mapped everything out like this.

|================================================================|

|DiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiDiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiD|

|isGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGi|

|is Gi|

|isGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGi|

|isssssssssssssssssSssssssssssssSssssssssssssS Gi|

|i GGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGi|

|i Gi|

|i GGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGi|

|D D|

|================================================================|

D = Diffuser. Each of these pokes its head about 2" out above the gravel.

Slots in each head will direct the water flow. The heads will screw in

to allow for changes in head design and direction. The tube from the

pump is in the right-back corner of the tank.

i = Tubing leading to the diffusers. Outside the tank, I will use a check-

valve leading to a loop-back to the sump. If the power shuts off, the

check valve opens when the feedback siphon starts, and air enters the

siphon. When the power comes on, the check valve closes because of the

water pressure from the pump. Any water that gets past the check valve

drains back to the sump.

S = Substrate drains. Each of these will have its own tube and siphon.

s = Tubing for substrate drains. Ball valves will allow flow control

into the high loop-back or the low loop-back, depending on the desired

siphon speed, or no siphoning at all. The substrate drain tubing will

exit in the left-back corner of the tank, along with the skimmer drain

tubing (not shown). Each substrate drain will have it's own tubing and

control valve.

G = Substrate aeration system. A small coupling in the diffuser tubing will

allow a small amount of water to enter the substrate aeration system.

The top of the substrate aeration system will be open to the air.

All control valves will be positioned outside the tank where they're easy

to get to. Quick-release couplings will make disassembly, cleaning, and

part replacement easy.

I will probably have to modify the sizes on the diffusers to get an even

flow out of each.

I also plan to use smaller holes in the substrate aeration system towards

the end with the inlet tube.

--------------------------------------------------

"Automatic vacuum" tank drain.

Designed by David W. Webb

dwebb-at-ti.com

The automatic vacuum uses a loop-back siphon design to keep from draining the

tank when it is in automatic mode. In high-speed mode, it will quickly drain

the tank.

I designed this drain after getting annoyed with having to vacuum the surface

of my gravel more often than I thought should be necessary. This tank drain

is intended for non-drilled tanks and tanks that can't be drilled safely.

This system relies on water motion within the tank to move debris to the

vacuum. A water-flow swirl in the tank will provide this motion. Note:

This system is designed with plant tanks in mind. Extra aeration procedures

may be necessary in a normal tank with a swirl water flow.

Blanket Disclaimer:

I am not responsible for any damage to personal property or injury to persons

if you use any of my suggestions or designs. I reserve the right to modify

my designs at any time.

__ C.-----------------D.

//\\ | ------------- |

|| =\\==================| |=== G.| | | |

|| # | | # ---- | | |

|| #~~~~~~~~~~~~~~~~~~~~| |~~# | -- ~| | |

|| # | | # | |F.| | | |

|| # | | # | | | | | |

|| # | | # | | | | | |

|| # | | # | | | | | |E.

|| # | | # | | | | | |

|| # A. | | # | | | | | |

|| #-at--at--at--at--at--at--at--at--at--at-###-at--at--at--at--at--at--at-| |-at--at-# | | | | | |

|| # | ------- | # | |J.| | | |

|| # B. ----------- # | == - |

|| ########################### | ==------

|| | |

\\________ I. | |

\________\ ---==----- |

\\ H.| -==-------

===||======| |=====

# || | #

# || | #

# || | #

# _||_ |----------#

#~| |~|~~~~~~~~~~#

# | | | #

###################

A. The gravel vacuum drain. This should be covered with a screen of some

sort to keep fish and gravel out. The screen should be removable and

cleanable. You want it fine enough to keep fish out, but coarse enough

to pull in debris. The drain should be as close to flush with the

substrate surface as is possible. It might be possible to lightly cover

the drain and surrounding area with coarse gravel to make it less

visible. I plan to use three drains arranged linearly across the bottom

of my 55 gallon tank. I currently have one, and it isn't enough. Each

drain will have its own parts A. B. C. and D. and will have its own

shut-off valve before they join at E.

B. The J-tube should be as low as possible in your tank. A good place to

put it is under the gravel.

The J-tube must be below the bottom of the waterfall (F.) The waterfall

will control the final resting water level of the tank when the pump is

off.

C. The siphon draws water out of the tank and into the velocity loop (E.)

D. An air fitting on the outside elbow of the siphon provides an easy way to

start the siphon.

Joseph S. Sellinger suggests that you connect this fitting to the air

venturii on one of your power heads. I believe that this will work

on higher flow power heads. Beware that for this application, the power

head needs to be in the tank and not in the sump, otherwise a siphon

in the air tubing could slowly drain the tank.

E. The velocity loop should drop as far down as is the tank is deep. The

velocity loop holds the water necessary to start or re-start the siphon.

F. The waterfall drains the siphoned water into the sump. The waterfall in

this application controls the resting water level of the tank when the

pump is off.

G. The surge tube allows you to fill the velocity loop to start the siphon.

It also acts to buffer water surges. The top of the surge tube should be

even with or above the top of the tank to prevent spilling any water

during a surge. (Surges may occur when you add water to the tank

rapidly.) You can reduce noise at this location by placing a drilled cap

loosely over the top of the surge tube. The drilled hole will prevent a

siphon from forming and draining your tank, and the cap will muffle the

sound of the water draining down the waterfall.

H. The drain into the sump. You may want to use a piece of filter material

suspended under this drain or use a settling tank to catch debris.

I. An individual shut-off valve for each drain.

J. The high-speed portion of the loop. A shut-off valve positioned here

controls whether this is on or not. If you leave this side of the loop

on for long, you will drain your tank. Good for flushing out the vacuum

system.

I recommend placing quick-disconnects at strategic places in this system so

you can easily tear it down for maintenance, modification, or repair.

David W. Webb

Enterprise Computing Provisioning

Texas Instruments Inc. Dallas, TX USA

(214) 575-3443 (voice) MSGID: DAWB

(214) 575-4853 (fax) Internet: dwebb-at-ti.com

(214) 581-2380 (pager) Text Pager: pgr-at-ti.com Subj:PAGE:David Webb

|

|

This page was last updated 29 October 1998 | ||